The ASCO Solenoid Valve PDF provides comprehensive insights into solenoid valve technology‚ including product listings‚ technical specifications‚ and application guidance. It serves as an essential resource for engineers‚ manufacturers‚ and maintenance professionals‚ offering detailed documentation to optimize system performance and compliance with industry standards.

Overview of ASCO Solenoid Valves

ASCO solenoid valves‚ part of Emerson’s portfolio‚ are renowned for their reliability and performance in fluid control systems. Designed for diverse applications‚ these valves offer precise control of fluids and gases‚ ensuring durability and minimal leakage. Available in various materials like brass or stainless steel‚ they cater to different industries‚ including medical‚ industrial‚ and marine sectors. Their compact design‚ high flow rates‚ and adherence to global certifications make them a preferred choice for engineers seeking efficient and compliant solutions. Their versatility and robust construction ensure long-term operational reliability.

Importance of the ASCO Solenoid Valve PDF

The ASCO Solenoid Valve PDF is a critical resource for professionals‚ offering detailed technical specifications‚ installation guidelines‚ and compliance information. It ensures users understand valve operation‚ maintenance‚ and troubleshooting‚ optimizing performance and safety. The document also highlights certifications like ATEX and SIL-4‚ ensuring adherence to industry standards. This comprehensive guide is indispensable for engineers‚ manufacturers‚ and technicians‚ providing the necessary tools to select‚ install‚ and maintain solenoid valves effectively across various applications.

History and Evolution of ASCO Solenoid Valves

Founded in 1927‚ ASCO has evolved into a global leader in solenoid valve technology. Acquired by Emerson‚ the brand expanded its product portfolio‚ introducing innovative valve series.

Founded in 1927

ASCO was established in 1927 by two entrepreneurs‚ Harry A. Smith and Frank A. Cooke‚ with a focus on creating innovative solenoid valve solutions. Initially‚ the company concentrated on developing reliable solenoid valves for industrial and pneumatic applications. Over the years‚ ASCO became a trusted name in fluid control technologies. In 1985‚ Emerson acquired ASCO‚ expanding its global reach and product offerings. This partnership enabled ASCO to innovate further‚ solidifying its reputation as a leader in solenoid valve manufacturing and technology advancement.

Emerson’s Acquisition and Expansion

In 1985‚ Emerson acquired ASCO‚ marking a significant milestone in the company’s growth. Emerson’s global resources and expertise enabled ASCO to expand its product portfolio and market reach. This acquisition drove innovation‚ leading to advanced solenoid valve solutions for diverse industries. Emerson’s support allowed ASCO to enter new markets‚ including hazardous areas and life sciences‚ while maintaining its commitment to quality and reliability. The partnership solidified ASCO’s position as a global leader in fluid control technologies.

Types of ASCO Solenoid Valves

ASCO offers a diverse range of solenoid valves‚ including Series 385‚ Series 055‚ Series 551‚ and Series 553. Each series is designed for specific applications‚ ensuring reliability and optimal performance across industries.

Series 385 Solenoid Operated Rocker Isolation Valves

ASCO Series 385 solenoid operated rocker isolation valves are designed for precise control in demanding applications. These valves feature a rocker isolation design‚ ensuring minimal fluid contact with moving parts. They are ideal for aggressive or corrosive media‚ offering high reliability and durability. The Series 385 is widely used in analytical and medical markets‚ providing consistent performance in low-flow and high-purity environments. The ASCO Solenoid Valve PDF details their specifications‚ materials‚ and suitability for challenging fluid control scenarios‚ making them a trusted choice for critical systems.

Series 055 Media-Separated Solenoid Valves

ASCO Series 055 media-separated solenoid valves are designed for applications involving aggressive or corrosive liquids. Featuring a PTFE body and diaphragm‚ these valves effectively isolate the solenoid from the fluid‚ ensuring durability and resistance to harsh chemicals. Their robust design allows for high-pressure operation and long service life. Suitable for demanding environments‚ the Series 055 valves are widely used in chemical processing‚ life sciences‚ and other industries requiring precise fluid control. The ASCO Solenoid Valve PDF provides detailed specifications and application guidelines for optimal performance.

Series 551 and 553 Solenoid Valves

ASCO Series 551 and 553 solenoid valves are compact‚ high-performance solutions for gas and fluid handling applications. Designed for versatility‚ these valves offer reliable operation in harsh environments and meet stringent marine industry standards with DNV-GL approval. Their robust construction ensures long service life‚ and they are ideal for systems requiring precise control. The ASCO Solenoid Valve PDF details their specifications‚ certifications‚ and installation guidelines‚ ensuring optimal performance in diverse industrial and marine settings while maintaining compliance with global regulations.

Applications of ASCO Solenoid Valves

ASCO solenoid valves are widely used in medical‚ analytical‚ industrial‚ and marine industries‚ ensuring precise fluid control in diverse applications‚ from hazardous areas to life sciences and single-use systems.

Medical and Analytical Markets

ASCO solenoid valves are highly utilized in medical and analytical markets for precise fluid and gas control in sensitive environments. Their compact design and media-separated technology ensure contamination-free operation‚ making them ideal for life sciences and single-use applications. Emerson’s ASCO Series 385 solenoid valves are optimized for these markets‚ offering reliable performance and compliance with strict industry standards. These valves are critical in medical devices‚ analytical instrumentation‚ and laboratory equipment‚ ensuring accuracy and safety in critical processes.

Industrial and Hazardous Areas

ASCO solenoid valves are engineered for reliability in industrial and hazardous environments‚ ensuring safe operation in explosive atmospheres. ATEX and IECEx certifications guarantee compliance for use in Zone 1 and Zone 2 areas. Direct-acting poppet valves with flameproof enclosures are designed to handle high-pressure and high-flow applications. Their compact‚ leak-tight construction minimizes risks in hazardous settings‚ making them ideal for oil‚ gas‚ and chemical industries where safety and durability are paramount.

Marine Industry Compliance

ASCO solenoid valves meet stringent marine industry standards‚ ensuring compliance with regulations for maritime applications. The ASCO 551 and 553 series are DNV-GL approved‚ guaranteeing reliability in marine environments. These valves are designed to withstand harsh conditions‚ offering compact solutions for fluid and gas handling. Their certification ensures adherence to marine safety protocols‚ making them ideal for applications requiring durable‚ compliant solenoid valve solutions in marine settings.

Life Sciences and Single-Use Applications

ASCO solenoid valves are integral to life sciences and single-use applications‚ addressing the demand for sterile‚ precise fluid control. Emerson’s ASCO Series 273 Pinch Valve is specifically designed for single-use batch processes in biopharmaceutical and medical applications. These valves offer lightweight‚ modular designs and ensure minimal contamination risks. Their compatibility with aggressive media and ability to handle high-purity fluids make them ideal for sensitive life science environments‚ supporting advancements in medical and analytical technologies with reliability and performance.

Certifications and Compliance

ASCO solenoid valves meet rigorous global standards‚ including ATEX‚ IECEx‚ and DNV-GL certifications‚ ensuring safe operation in hazardous areas‚ marine environments‚ and life science applications.

ATEX and IECEx Certification

ASCO solenoid valves are ATEX and IECEx certified‚ ensuring safe operation in hazardous environments. These certifications validate their design for explosive atmospheres‚ adhering to global safety standards. The valves feature flameproof enclosures and direct-acting poppet technology‚ ideal for actuator control in high-risk areas. Compliance with TÜV IEC 61508 functional safety standards up to SIL-4 further enhances reliability. This certification ensures ASCO valves meet rigorous requirements for safety‚ durability‚ and performance in demanding industrial applications worldwide.

DNV-GL Approval

ASCO 551 and 553 solenoid valves hold DNV-GL approval‚ ensuring compliance with marine industry standards. This certification confirms their suitability for marine environments‚ adhering to strict regulations for safety and performance. The valves are compact‚ designed for gas and fluid handling applications‚ and feature schematic diagrams for clear operation. DNV-GL approval guarantees reliability‚ durability‚ and adherence to maritime requirements‚ making these valves ideal for marine-based systems and applications requiring robust fluid control solutions.

Functional Safety Certification (SIL-4)

The ASCO solenoid valves meet the rigorous Functional Safety Certification (SIL-4)‚ ensuring high reliability in critical safety systems. This certification‚ based on the TÜV IEC 61508 standard‚ confirms their suitability for applications requiring the highest levels of safety integrity. SIL-4 compliance guarantees minimal failure rates‚ making these valves ideal for industries like oil & gas‚ chemical processing‚ and other high-risk environments. This certification underscores Emerson’s commitment to delivering products that meet the most stringent safety and performance standards globally.

Technical Specifications

The ASCO solenoid valves feature high-quality construction materials‚ wide pressure ratings‚ and precise flow control. They offer versatile electrical connections and comply with global industry standards for reliable performance.

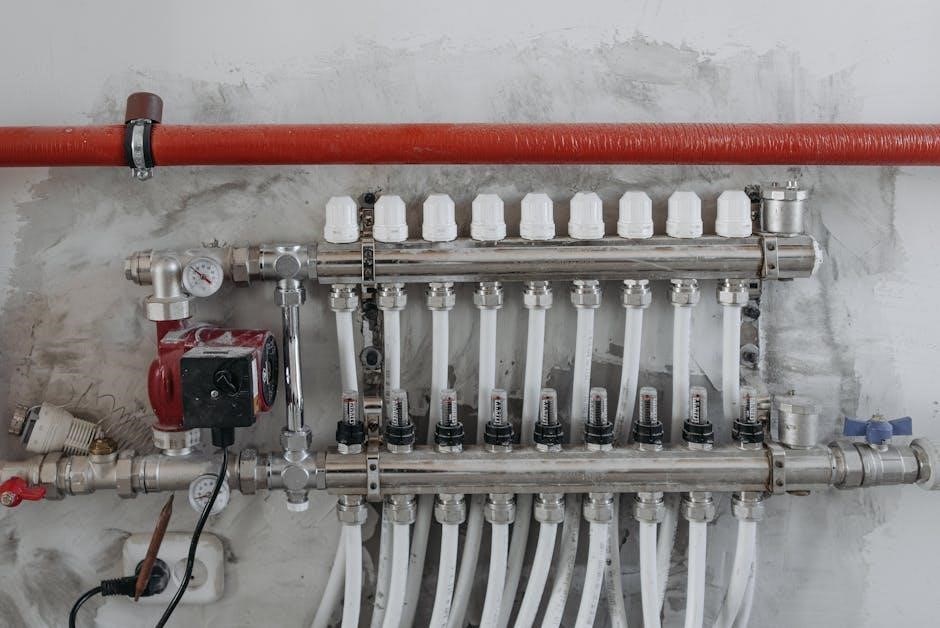

Construction Materials and Design

ASCO solenoid valves are built with durable materials like stainless steel‚ brass‚ and PTFE for corrosion resistance and longevity. Their robust design ensures minimal leakage and high performance. The valves feature a compact‚ leak-tight assembly with epoxy-encapsulated coils for reliable operation. Media-separated designs isolate internal components from aggressive fluids‚ while direct-acting and rocker isolation models offer precise control. These constructions cater to diverse applications‚ ensuring compatibility with hazardous areas and stringent industry standards.

Pressure and Flow Ratings

ASCO solenoid valves offer a wide range of pressure and flow ratings to suit diverse applications. Models like the Series 385 deliver high flow rates up to 1400 l/min‚ while others handle pressures up to 20 bar. Valves are designed for compatibility with both gases and liquids‚ ensuring precise control in demanding environments. High-pressure models‚ such as the Series 551 and 553‚ are engineered for robust performance‚ while media-separated designs maintain optimal flow under varying conditions‚ making them adaptable to industrial and hazardous applications;

Electrical Connections and Coils

ASCO solenoid valves feature advanced electrical connections and coils designed for reliable performance in various applications. The epoxy-encapsulated Red Hat II solenoid ensures protection against harsh environments. Coils are available in Class F ratings for high-duty cycles and long service life. With direct-mount designs and spade-plug connectors‚ installation is simplified. Temperature ranges span from 32°F to 125°F for AC coils and 32°F to 104°F for DC‚ ensuring compatibility with diverse operating conditions. These features ensure efficient control and durability in industrial and hazardous environments.

Installation and Maintenance

Proper installation ensures optimal performance. Follow wiring diagrams and maintenance tips to extend lifespan. Refer to the PDF for detailed installation and maintenance guidance.

Wiring Diagrams and Instructions

The ASCO Solenoid Valve PDF includes detailed wiring diagrams to ensure proper electrical connections. Step-by-step installation guides are provided to simplify the process. Troubleshooting sections help identify common issues and solutions. Clear instructions are given for coil connections‚ ensuring compatibility with control systems. Compliance with safety standards is emphasized‚ making the documentation a reliable resource for engineers and technicians. Proper wiring ensures optimal valve performance and longevity‚ while adhering to industry regulations and safety protocols.

Maintenance Tips and Troubleshooting

Regular maintenance ensures optimal performance of ASCO solenoid valves. Inspect solenoid coils for damage and ensure proper wiring connections. Clean valve orifices to prevent clogging from debris. Replace worn or damaged seals and diaphragms promptly. For troubleshooting‚ check for power supply issues‚ coil faults‚ or fluid incompatibility. Lubricate moving parts periodically to maintain smooth operation. Refer to the ASCO Solenoid Valve PDF for detailed diagnostic guides and repair procedures. Proper maintenance extends valve lifespan and prevents unexpected failures‚ ensuring reliable system operation and safety compliance.